Die casting has indeed played a crucial role in manufacturing for decades, and China’s ascent as a significant figure in this sector cannot be overstated. With its adeptness in crafting china molds and components of exceptional quality, China has solidified its position as a pivotal hub for die casting on a global scale. The country’s dedication to refining its techniques and processes has earned it a reputation for excellence in the industry. Consequently, manufacturers from around the world increasingly rely on China for their die casting needs, recognizing the unparalleled expertise and reliability it offers.

I. Introduction

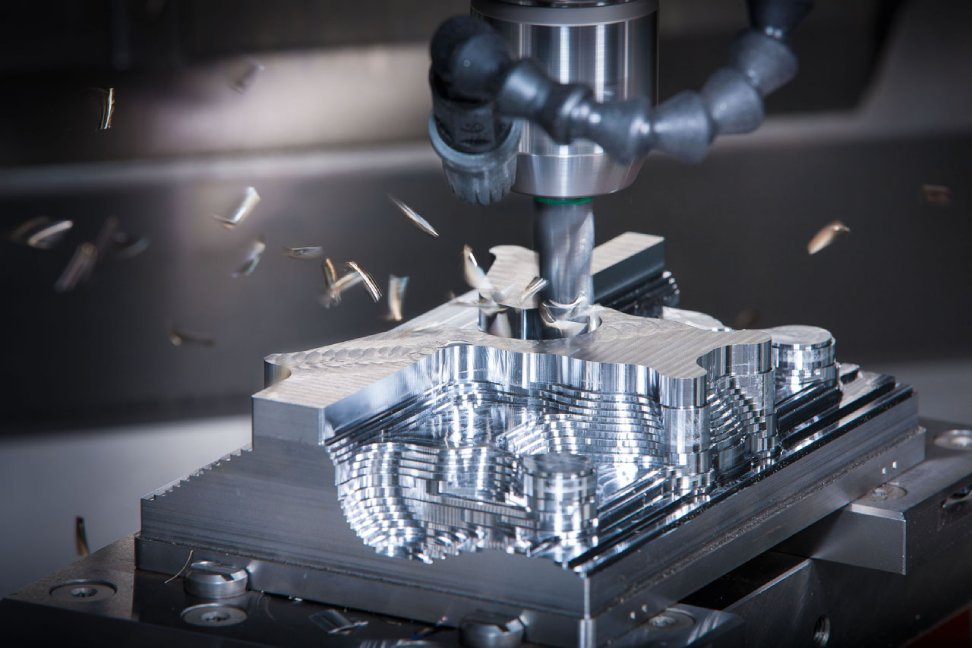

Die casting is a manufacturing process that involves injecting molten metal into a mold cavity under high pressure. The mold used in this process plays a crucial role in determining the final quality of the product. In recent years, China has gained significant traction in the global die casting market due to its expertise in producing top-notch molds, commonly referred to as China molds.

II. Evolution of Die Casting in China

A. Historical Background

China’s journey in the die casting industry dates back to several decades ago when the country started to invest in modern manufacturing technologies. Initially, die casting operations were limited to a few regions, but with the government’s support and technological advancements, the industry witnessed exponential growth.

B. Growth and Development

Over the years, China has evolved into a powerhouse in the die casting sector, attracting investments from multinational corporations and establishing itself as a preferred destination for outsourcing die casting services. The country’s abundant skilled labor force and cost-effective production capabilities have further fueled its growth in this sector.

III. Advantages of China Mold in Die Casting

A. Cost-effectiveness

One of the primary reasons behind the popularity of China mold die casting is its cost-effectiveness. The lower labor and production costs in China enable manufacturers to offer competitive pricing without compromising on quality.

B. Quality and Precision

Despite its cost advantages, China mold die casting is known for its exceptional quality and precision. Chinese manufacturers leverage advanced technologies and stringent quality control measures to ensure that the final products meet international standards.

C. Versatility

China mold die casting offers unparalleled versatility, allowing manufacturers to produce a wide range of components with varying complexities. Whether it’s automotive parts, consumer electronics, or aerospace components, China molds can cater to diverse industry requirements.

IV. Challenges and Solutions

A. Quality Control

Maintaining consistent quality standards can be challenging, given the scale of die casting operations in China. However, manufacturers are increasingly investing in advanced quality control systems and certifications to address this issue.

B. Intellectual Property Concerns

Intellectual property (IP) theft has been a longstanding concern for companies operating in China. To mitigate this risk, manufacturers often implement strict confidentiality agreements and work closely with trusted partners.

C. Environmental Impact

The die casting process, like any other manufacturing activity, has environmental implications. To minimize its environmental footprint, the Chinese government has been encouraging the adoption of sustainable practices and the use of eco-friendly materials.

V. Trends and Innovations

A. Automation and Robotics

Automation and robotics are reshaping the die casting landscape in China, improving efficiency, reducing labor costs, and enhancing product consistency. Advanced robotic systems are increasingly being integrated into die casting facilities to streamline production processes.

B. Sustainable Practices

As environmental concerns continue to escalate, sustainability has become a key focus area for die casting manufacturers in China. From implementing energy-efficient technologies to recycling waste materials, companies are actively seeking ways to reduce their environmental impact.

VI. Future Outlook

A. Market Projections

The future of China mold die casting looks promising, with market analysts forecasting continued growth in the coming years. Factors such as increasing demand from end-user industries and ongoing technological advancements are expected to drive this growth trajectory.

B. Technological Advancements

Innovation remains at the forefront of China’s die casting industry, with ongoing research and development efforts aimed at enhancing process efficiency, product quality, and sustainability. From 3D printing to advanced alloy formulations, the industry is poised for significant advancements.

VII. Conclusion

China mold die casting China has indeed revolutionized the global manufacturing industry, providing unparalleled cost-effectiveness while maintaining superior quality standards. The robust infrastructure and extensive expertise of China’s workforce have played pivotal roles in this transformation. Moreover, China’s unwavering commitment to innovation ensures that its die casting sector stays at the forefront of technological advancements, constantly raising the bar for excellence. As a result, manufacturers worldwide increasingly turn to China for their die casting needs, recognizing the unmatched value proposition it offers. With each advancement and refinement, China solidifies its position as a leader in die casting, shaping the future of manufacturing.

Additional:

- Mark Mateschitz – Net Worth, Lifestyles, Business

- Gianluigi Aponte – Net Worth, Lifestyles, Business, Companies

- Jacqueline Mars – Net Worth, Lifestyles, Business, Companies